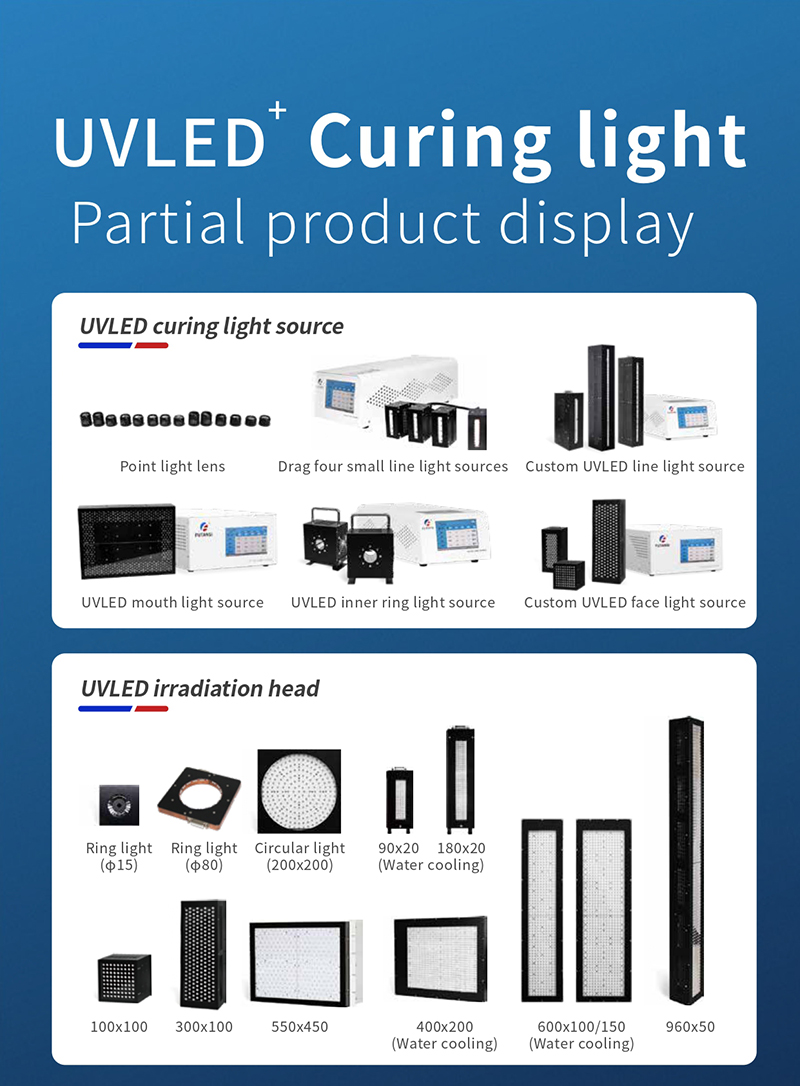

Special-Shaped LED UV curing system

custom UVLED curing system- Wave365/385/395/405nm(Customised)

- ApplicationsUV glue/resin/ink curing

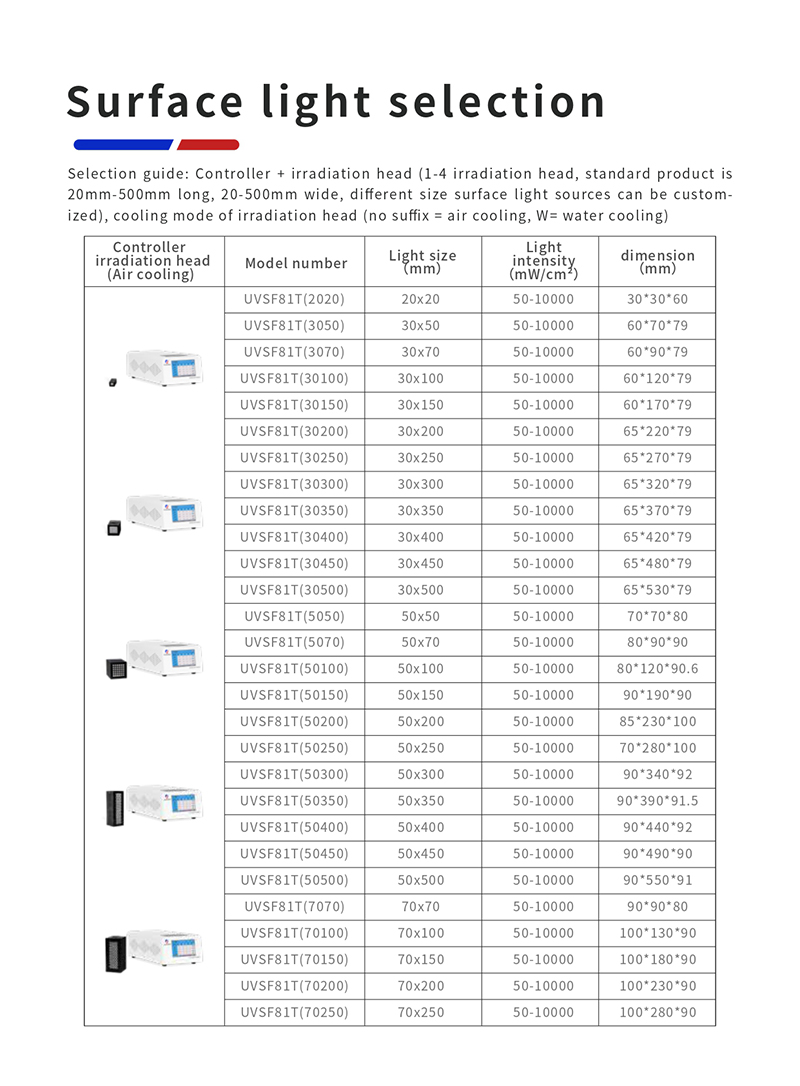

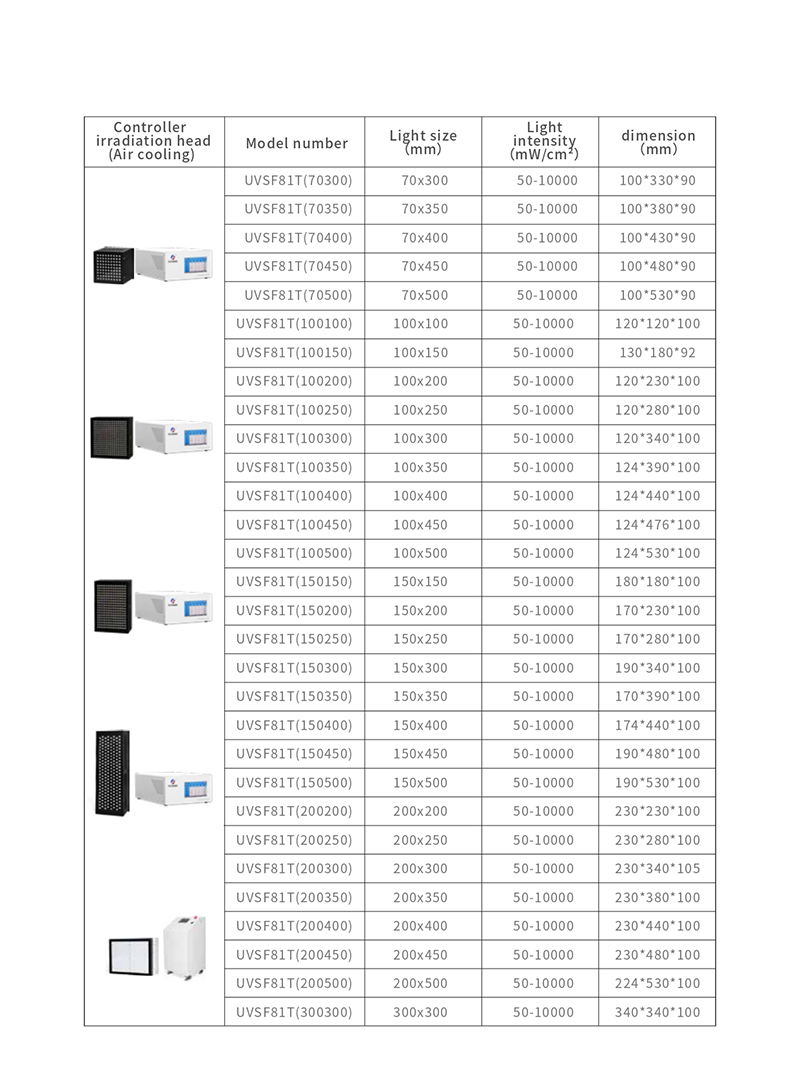

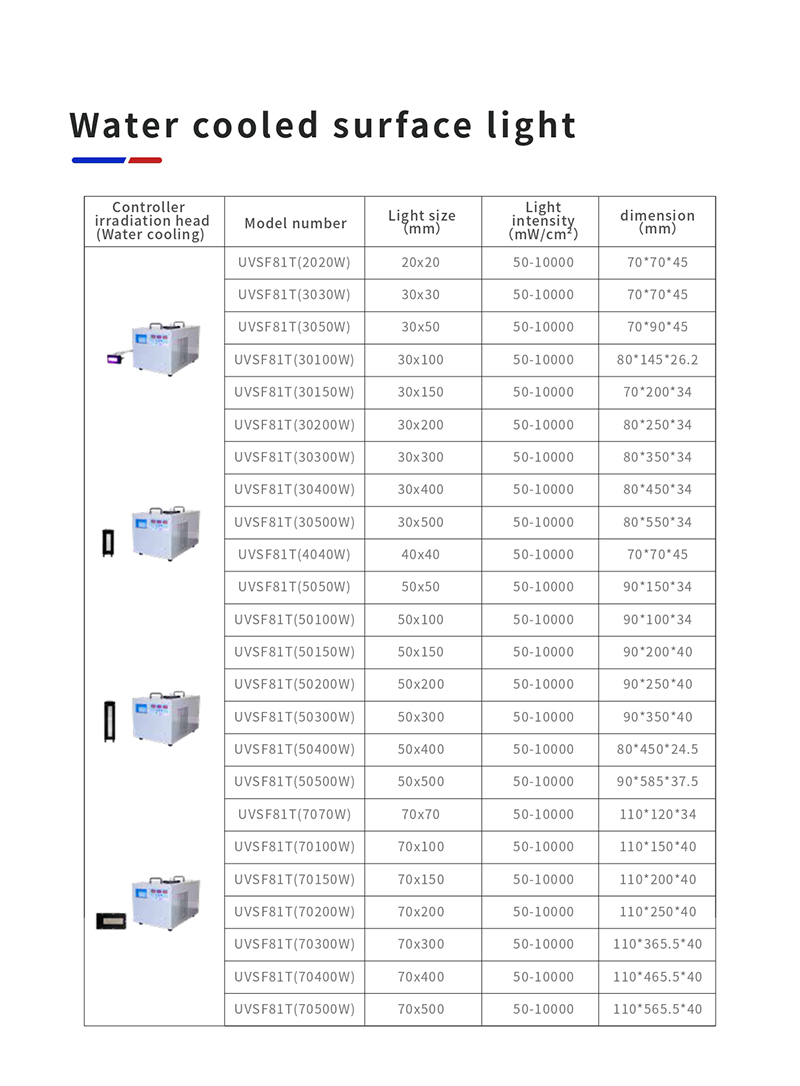

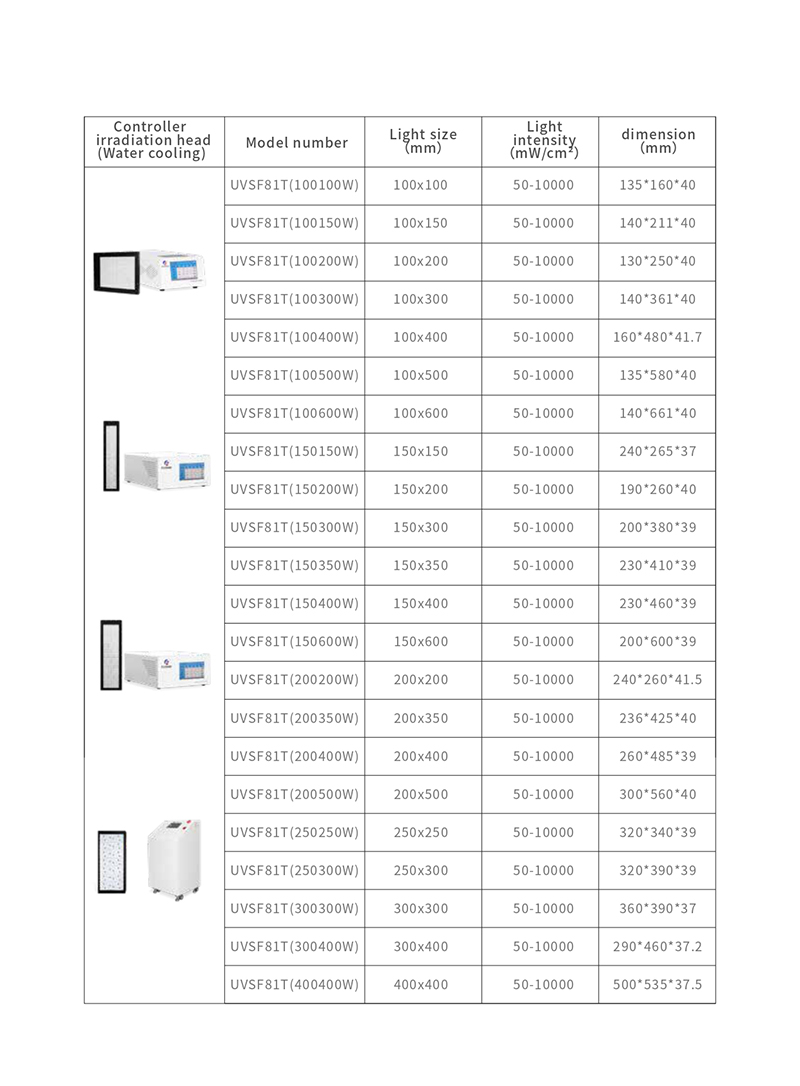

- Luminous size20mm-500mm long, 20-500mm wide

- CoolingFans / Water Cooling

- Light intensity10-10000mW/cm²

Related product literature downloads

Brief description of this special-shaped UVLED curing system

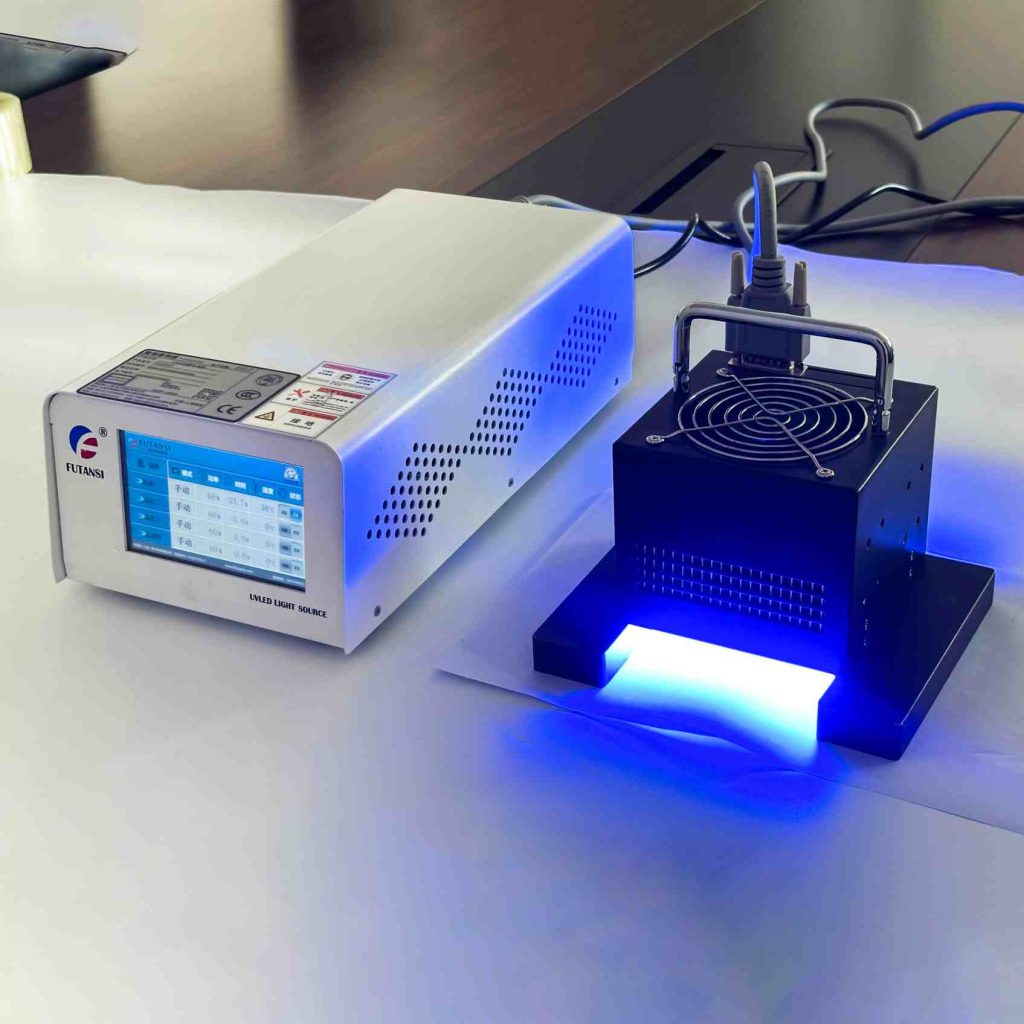

A custom-made, special-shaped UV LED curing system is a compact and specialized device designed to precisely cure ultraviolet (UV) curable materials in a circular or ring-shaped configuration. Here’s a brief introduction to its key features and applications:

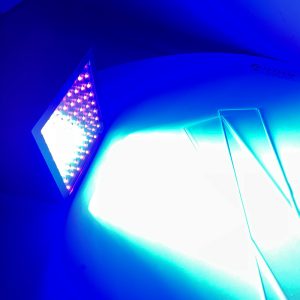

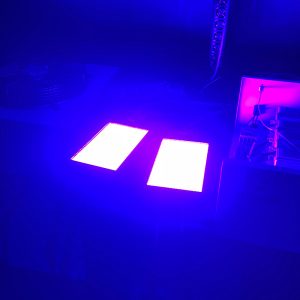

1. Customized Design: The distinctive feature of the mini-circle UV curing system is its circular or ring-shaped configuration. This design enables uniform and consistent UV light exposure across the entire circumference of the cured material.

2. UV LED Light Source: Equipped with a UV curing light, typically in the UVA range(365nm and 405nm), the custom UV LED curing system emits the necessary wavelengths for the curing of UV curable materials. The circular arrangement ensures that the material is exposed to UV curing light from all angles, promoting comprehensive and even curing.

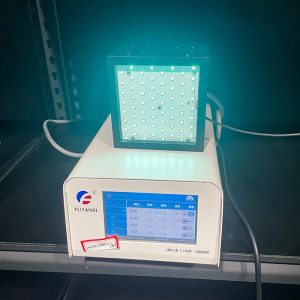

3. Compact Size: The customized LED UV curing system is characterized by its compact size, making it suitable for applications where space is limited. Its small footprint is advantageous for tabletop use, research environments, or small-scale production setups.

4. Adjustable Parameters: All of Futansi’s UV LED curing systems come with adjustable parameters, such as curing time, intensity, and temperature. This flexibility enables users to tailor the curing process to meet the specific requirements of the materials being cured.

5. Versatility: The circular design enhances the versatility of the UV curing systems, making it suitable for curing various UV curable materials, including UV adhesives, coatings, UV inks, and UV resins. Its adaptability makes it useful in applications such as electronics, optics, and medical device manufacturing.

6. Energy Efficiency: These UV LED curing systems often incorporate energy-efficient UV curing lamps, contributing to lower operational costs. The focused circular design helps maximize the efficiency of UV light exposure, promoting effective curing with minimal energy consumption.

7. User-Friendly Controls: Typically, LED UV curing systems are designed with user-friendly controls, allowing operators to easily set parameters, monitor the curing process, and make adjustments as needed. Intuitive interfaces contribute to the ease of use.

8. Safety Features: To ensure safe operation, these LED UV curing systems are typically equipped with safety features such as interlocks and shielding to protect operators from exposure to UV curing light.

In summary, the customized UV LED curing system is a compact and efficient tool designed for curing UV curable materials in a circular exposure configuration. Its specialized design and small footprint make it a valuable asset for applications where precision curing with a circular exposure pattern is essential.

Product Applications

Futansi UVLED curing systems are designed for the rapid curing of UV curable glues, inks, varnishes, paints, and coatings. The resulting finish is high-gloss, weather-, water-, abrasion-, and chemical-resistant, providing long-term surface protection. LED-UV technology covers a broad industrial spectrum, especially in ink printing and general product finishing. Typical uses include:

1、optical communication industry

active devices, passive device packaging, optical fiber optical cable coating curing bonding;

2、photovoltaic new energy

photovoltaic chips, lithium battery module curing;

3、semiconductor materials

wafer chips, uv film debonding;

4、medical devices

medical catheters, syringes, endoscopes, infusion tubes and other medical devices sealing;

5、3C electronics

mobile phone parts, digital camera accessories, motor components, semiconductor chips, sensors, encoders, etc.;

6、PCB circuit board

electronic components fixed, core circuit potting, chip protection, antioxidant coating protection;

7、optical parts

lens modules, optical lenses, infrared night vision assembly bonding;

8、liquid crystal display

surface edge encapsulation.

9、laboratory materials

polymer chemistry, semiconductor materials light curing;

10、ink printing

screen printing label printing.

Product Advantages

1、LED lamp chip

Advantages such as high energy, strong light and long service life;

2、Single-band LED ultraviolet light source

common wavelengths of 365nm, 385nm, 395nm, 405nm, no thermal radiation;

3, UVLED curing light source with lower heat radiation

Using high power LED lamp beads, emitting 365/385/395/405nm single-band UV light source, no infrared wavelength, the irradiated substrate surface temperature rise of no more than 5 ℃, no thermal radiation damage to the substrate surface, suitable for heat-sensitive material surface drying;

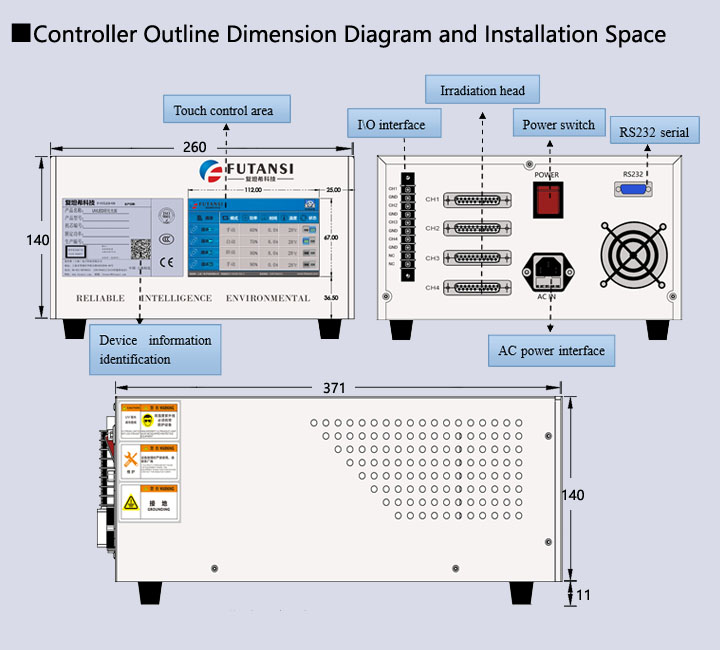

4、Multi-channel working mode

Standard with a UVLED light source equipment, according to the actual use of the situation, choose 1-4 irradiation heads alone or synchronous work, no need to repeat the purchase of light source equipment, effective cost savings;

5、Low power consumption

Through the LED chip for electrical energy, light energy conversion, less energy loss, low power consumption, about one tenth of the traditional UV mercury lamp, can save a lot of electricity consumption each year.

6、Clean and environmental protection without pollution

Does not contain mercury metal harmful substances, does not produce ozone when used, and belongs to a clean and environmentally friendly energy.

7, small size, small footprint

UVLED curing machine covers an area far less than the traditional UV mercury lamp, can be customized in shape, size, and irradiation area, the average size of about 1/10 of the UV lamp type, lightweight, small physical strength, suitable for use in different working environments;

8、Long service life

UVLED emits ultraviolet light through an LED chip. Its use time is more than 20,000h on average, compared to the traditional UV mercury lamp service life (average use time is about 800h) is much longer, can instantly light up/off led ultraviolet light source, not affected by switch closure;

Download support

We support the download of relevant product manuals in PDF format, if you need special customized products, please contact our customer service by phone or email on the right

A professional manufacturer of UVLED curing systems

A professional manufacturer of UVLED curing systems