Choosing the Right Wavelength in UV Curing: A Guide for Optimal Performance

1787A Guide for choosing the Right Wavelength in UV Curing

View detailsSearch the whole station

In materials analysis and quality testing, metallographic sample preparation is a critical step for revealing material microstructures. Traditional thermal-curing mounting processes are time-consuming and inefficient, and the high-temperature environment can easily cause irreversible damage to heat-sensitive samples. The emergence of UVLED curing technology provides a revolutionary solution to this bottleneck, elevating sample preparation efficiency and quality to new heights.

Technical Principle: Precise Control of Photochemical Crosslinking

The UVLED curing system emits narrow-spectrum UV light with peak wavelengths of 365nm or 395nm through high-power UV LED chips, precisely activating photoinitiator molecules in the photosensitive resin. This triggers a chain crosslinking reaction within tens of seconds, rapidly polymerizing the liquid resin into a high-strength solid. Compared with traditional mercury lamps, the cold light source characteristic of LEDs eliminates infrared thermal radiation, controlling temperature rise on the sample surface to within 5°C and ensuring the original microstructure remains undamaged.

Core Advantages: Four Key Values

Green Economy: Energy consumption is reduced by 75%, LED lifespan reaches 20,000 hours, with no mercury or ozone emissions, and comprehensive operating costs are only 1/3 of traditional equipment.

Efficiency Disruption: Curing time is dramatically reduced from the traditional 2-4 hours to 30 seconds-5 minutes, increasing single-batch sample preparation volume by 8-10 times and significantly shortening R&D cycles.

Quality Assurance: The heat-damage-free characteristic enables perfect mounting of heat-sensitive samples such as plastics, coatings, and electronic components, with edge retention >99%, eliminating cracks and deformation.

Intelligent Precision: The digital control system enables stepless adjustment of light intensity from 0-100%, with illumination uniformity ≥95% and timing accuracy of ±0.1 seconds, ensuring batch-to-batch repeatability.

Typical Application Scenarios

Metallographic Mounting: Suitable for cold-mounting resins such as epoxy and acrylate, achieving post-curing hardness of Shore D 85 and above, with excellent grinding/polishing resistance, particularly ideal for cross-section analysis of PCBs, composite materials, and surface treatment layers.

Functional Coatings: Rapidly constructs anti-corrosion, wear-resistant, or optical coatings on metal surfaces, with curing speed increased by 20× and adhesion improved by 30%.

Microstructure 3D Printing: Combined with DLP technology, enables high-precision microstructure fabrication at the 5μm scale, widely applied in microfluidic chip and precision mold manufacturing.

Electronics Packaging: Rapid photoresist patterning with curing depth up to 5mm without gradient, meeting high-reliability requirements for semiconductor packaging.

Product Configuration Recommendations

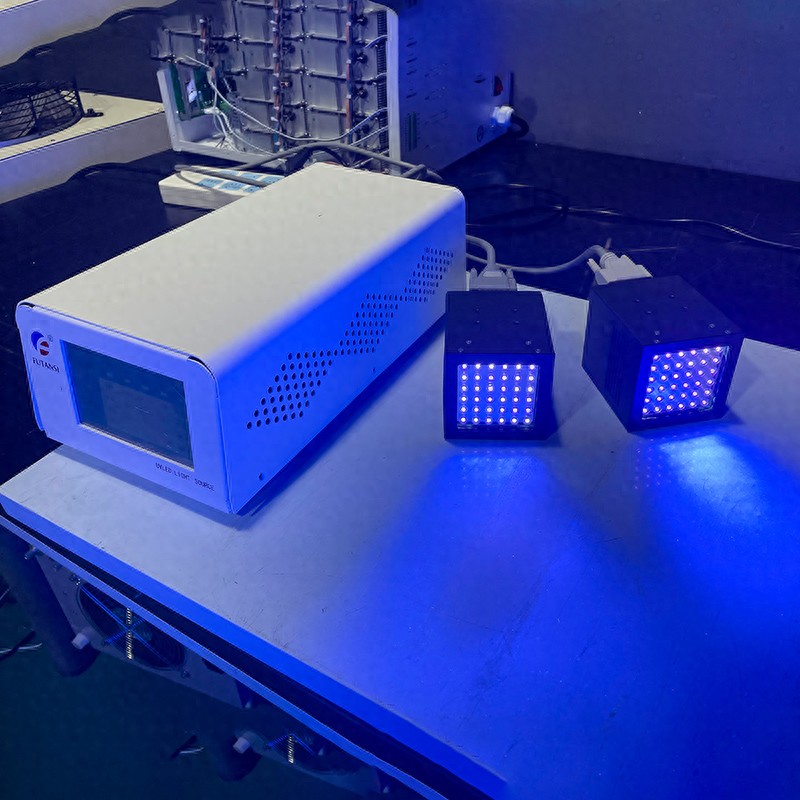

Professional-grade UVLED curing equipment should feature multi-wavelength switching modules, intelligent touch control systems, air-cooled heat dissipation, and door-controlled safety interlock devices. Recommended specifications include adjustable light intensity output of 5-20W/cm² and an irradiation area covering 100×100mm to accommodate various sample preparation requirements.

Upgrade your sample preparation process immediately and experience a dual leap in efficiency and precision.

A Guide for choosing the Right Wavelength in UV Curing

View detailsinner ring UV LED curing light source are widely used in industrial applications, providing fast and efficient curing for a range of materials

View detailscustomized uv led curing systems can be designed to fit a wide range of applications and workpieces. Whether it's a flat surface, a curved shape, or a complex three-dimensional structure, customised UV curing lights can be tailored to fit the uniq...

View detailsHigh power UV LED curing systems with a 200x200mm curing area are ideal for large-scale industrial applications, providing fast and efficient curing for a range of materials.

View detailsHelloPlease log in

This topic is so relevant right now. Thanks for the timely post.

2025-12-1713:59

Great mix of research and practical application. Very helpful.

2025-12-1907:59

Awesome! Its genuinely remarkable post, I have got much clear idea regarding from this post

2026-01-1106:40

fatik cerrahpaşa eskort

2026-01-1222:50

Good post! We will be linking to this particularly great post on our site. Keep up the great writing

2026-01-1303:30

I really like reading through a post that can make men and women think. Also, thank you for allowing me to comment!

2026-01-1504:35

기능사시험문제 정리된 글은 북마크해두고 계속 보게 되네요.

2026-01-1610:28

Great information shared.. really enjoyed reading this post thank you author for sharing this post .. appreciated

2026-01-1706:12

Wonderful post — very practical, detailed, and easy to follow.

2026-01-1903:18

Justin

2026-01-1908:08

For the reason that the admin of this site is working, no uncertainty very quickly it will be renowned, due to its quality contents.

2026-01-1908:48